Introduction to Calcium Carbonate in the Oil and Gas Industry

Calcium carbonate is an essential component in the oil and gas industry. It has a wide range of applications and benefits, making it a crucial element in the extraction, processing, and transportation of petroleum products. In this article, we will explore the various uses of calcium carbonate in the oil and gas industry, and discuss how it contributes to the efficiency and effectiveness of industry processes.

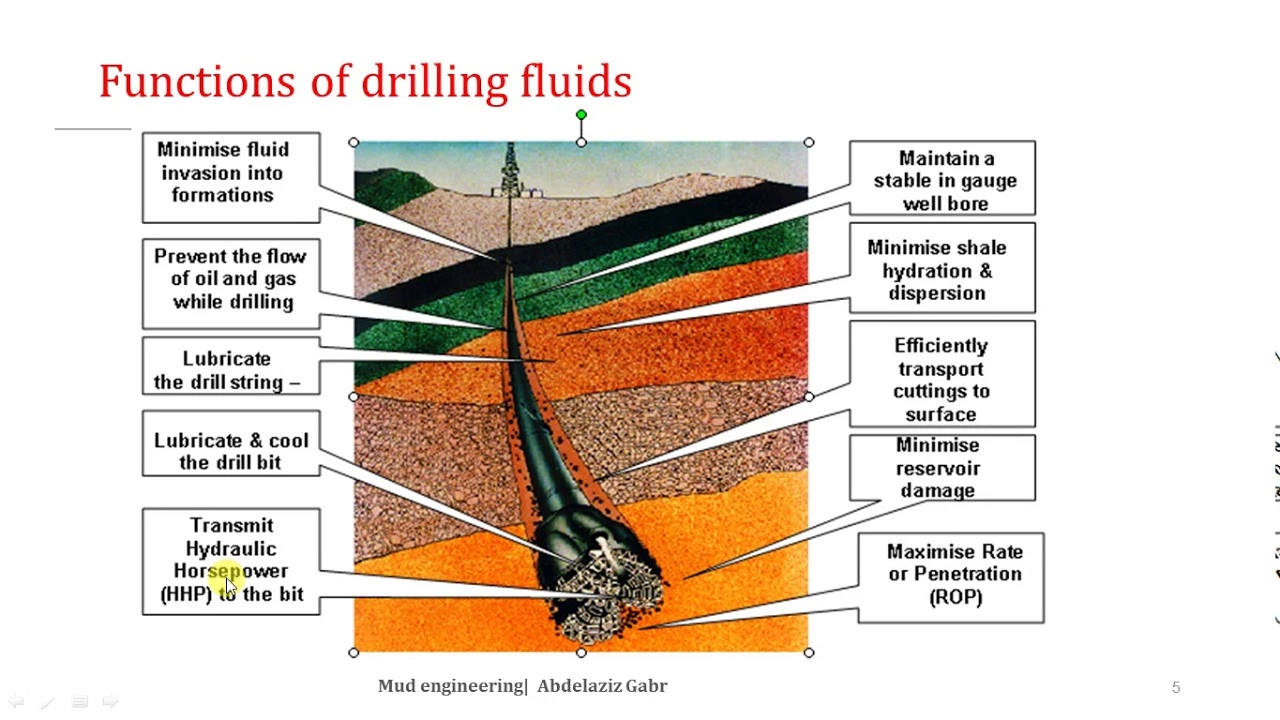

Boosting Drilling Fluid Performance

Drilling fluids, also known as drilling muds, are used in the drilling process to aid in the removal of cuttings from the borehole, cool and lubricate the drill bit, and maintain the pressure and stability of the well. Calcium carbonate is often added to drilling fluids as a weighting agent, helping to increase the fluid's density and viscosity. This not only improves the overall performance of the drilling fluid but also helps to prevent the formation of gas bubbles, which can lead to well control issues and potential blowouts.

Formation Damage Prevention

During the drilling process, it is essential to protect the formation from damage caused by the invasion of drilling fluids. Calcium carbonate is used as a bridging agent and sealant, helping to prevent the penetration of drilling fluids into the formation. By sealing off the pores and fractures in the formation, calcium carbonate helps to maintain the integrity of the reservoir and ensure that hydrocarbon production is not compromised.

Enhancing Cementing Operations

Cementing is a crucial step in the completion of a well, as it provides structural support and seals off the annular space between the casing and the formation. Calcium carbonate is a key ingredient in oil well cement formulations, as it reacts with the cement's acidic components to form a stable and durable cement matrix. This not only improves the strength and integrity of the cement but also helps to prevent the migration of formation fluids and gases into the wellbore.

Acidizing Treatment Enhancer

Acidizing treatments are used to stimulate production from oil and gas wells by dissolving and removing formation damage, scale, and other blockages. Calcium carbonate is often used as an acidizing treatment enhancer, as it acts as a temporary filler material that can be easily removed once the treatment is complete. It helps to protect the wellbore and the surrounding formation from damage caused by the acidizing treatment, ensuring that the well remains productive and efficient.

Scale Inhibition and Removal

Scale formation is a common issue in the oil and gas industry, as it can lead to reduced production rates, equipment damage, and increased operational costs. Calcium carbonate is widely used as a scale inhibitor and remover, as it helps to prevent the precipitation of scale-forming minerals and dissolve existing scale deposits. By keeping production equipment and pipelines free of scale, calcium carbonate helps to improve the efficiency of oil and gas operations and reduce the risk of costly downtime.

Corrosion Protection

Corrosion is a major concern in the oil and gas industry, as it can lead to equipment failure, environmental damage, and potential safety hazards. Calcium carbonate is a natural corrosion inhibitor, as it forms a protective layer on the surface of metal equipment, preventing the penetration of corrosive substances. This not only extends the life of the equipment but also helps to maintain the integrity of the well and minimize the risk of leaks and spills.

Waste Management and Environmental Compliance

Proper waste management is essential in the oil and gas industry, not only to minimize the environmental impact of drilling operations but also to comply with strict regulations and guidelines. Calcium carbonate is used in the treatment and disposal of drilling waste, as it helps to neutralize acidic contaminants and solidify liquid waste for safe and efficient disposal. By utilizing calcium carbonate in waste management processes, oil and gas companies can ensure that they are meeting their environmental responsibilities and maintaining the highest standards of operation.

Conclusion: A Vital Component in the Oil and Gas Industry

Calcium carbonate is an essential component in the oil and gas industry, playing a vital role in a wide range of applications and processes. From enhancing drilling fluid performance and preventing formation damage, to improving cementing operations and protecting equipment from corrosion, calcium carbonate is a versatile and valuable asset in the extraction, processing, and transportation of petroleum products. By understanding and utilizing the benefits of calcium carbonate, oil and gas companies can improve the efficiency, effectiveness, and sustainability of their operations, ensuring a successful and profitable future for the industry.

9 Comments

Calcium carbonate is the unsung hero of the rig, the secret sauce that keeps the mud from blowing up and the well from turning into a disaster zone! 💥💣 It's the heavyweight champion of density, and if you think you can ditch it, you're flirting with catastrophe. Keep it in the mix and the whole operation runs like a well‑tuned orchestra! 🎶

Calcium carbonate really helps keep things running smoothly in the field its versatility is a huge plus for everyone involved. It's great to see such reliable solutions

In the grand tapestry of petroleum engineering calcium carbonate emerges as a subtle yet profound catalyst its presence whispers of ancient seas and modern technology alike its role in sealing formations transcends mere utility becoming an embodiment of geological stewardship 🙂 the industry ought to reflect upon this mineral with reverence rather than mere commercial calculation

From a petro‑mechanical perspective the incorporation of CaCO₃ within drilling mud matrices constitutes a non‑negotiable parameter for rheological stability and downhole pressure equilibrium the interfacial tension mitigation afforded by micronized carbonate particles directly correlates with reduced formation permeation risk and enhances cement sheath integrity thereby upholding industry best‑practice protocols

Calcium carbonate does its job but the hype often overshadows more innovative alternatives

Calcium carbonate is indeed a cornerstone of many hydrocarbon extraction processes; its multifaceted functionality spans from rheology modulation to environmental compliance, thereby ensuring operational continuity across diverse geological settings. When introduced into drilling fluids, its fine particulate nature elevates fluid density, mitigates the formation of gas channels, and enhances cuttings removal efficiency, which collectively reduces the risk of well control incidents. Moreover, its role as a sealing agent within formation damage prevention is indispensable; by bridging pore throats, it preserves reservoir permeability and safeguards production potential. In cementing operations, the carbonate reacts with acidic components of the cement slurry, forming a robust matrix that resists compressive stresses and fluid migration, which is critical for long‑term well integrity. The acidizing treatment enhancer applications further demonstrate its versatility, acting as a sacrificial filler that shields the formation from aggressive acid exposure while still permitting controlled dissolution post‑treatment. Scale inhibition properties arise from its ability to complex with divalent cations, thereby preventing precipitation of deleterious mineral scales that could impair flow lines and processing equipment. Additionally, as a natural corrosion inhibitor, calcium carbonate deposits a passive film on metal surfaces, reducing electrochemical attack and extending service life of downhole hardware. Finally, its incorporation into waste management protocols, such as neutralizing acidic drilling effluents and solidifying liquid waste, exemplifies a sustainable approach to environmental stewardship in the oil and gas sector.

Calcium carbonate is just filler

I totally get why people rely on calcium carbonate its like a safety net for wells 😊 but sometimes i wonder if we’re over‑relying on the same old chemistry it’d be nice to see some fresh research in the mix

Oh, what a revelation, calcium carbonate saving the day in every oilfield operation.

Who would have thought that a simple mineral could masquerade as a miracle worker?

We’re supposed to applaud its ability to tweak mud density, as if that isn’t the baseline requirement for any decent drilling fluid.

And let’s not forget its groundbreaking talent in plugging pores, a skill that has apparently earned it a spot on the industry’s Hall of Fame.

The cement formulations love it, because without calcium carbonate the cement would just be a weak, crumbly paste that leaks like a busted pipe.

In acidizing treatments it plays hero, temporarily filling voids, only to vanish later like a magician’s assistant.

Scale inhibition? Oh yes, another miracle – because we all know scale is the ultimate nightmare of every pipeline.

Corrosion protection is also on its résumé, forming a protective film that supposedly makes metal last forever.

Waste management benefits are highlighted too, neutralizing acids and solidifying waste as if it were a household chore.

All this sounds impressive until you realize that all these benefits are simply the result of basic chemistry.

There’s nothing mystical about calcium carbonate; it’s just calcium, carbon, and oxygen doing what any competent chemist expects.

Yet the industry writes sonnets about it, as if we should be grateful for oxygen’s contribution to rock formation.

Meanwhile, we could be investing in real innovation, but instead we glorify an old‑school additive.

The narrative continues to inflate its importance, drowning out discussions about sustainable alternatives.

So, let’s raise a toast to calcium carbonate, the ever‑reliable sidekick that never gets a starring role.

After all, why chase progress when you can cling to the comfort of a mineral that’s been around for millennia?