Pharmaceutical Manufacturing: How Drugs Are Made, Tested, and Regulated

When you pick up a pill at the pharmacy, you’re holding the result of pharmaceutical manufacturing, the complex process of producing medications under strict scientific and regulatory standards. Also known as drug production, it’s not just mixing chemicals—it’s a multi-step, highly controlled system designed to ensure every dose is safe, effective, and identical to the last. Behind every generic pill or brand-name tablet is a factory where purity, consistency, and safety are non-negotiable.

There’s a big myth that generic drugs are made in shady labs. That’s not true. The same FDA, the U.S. agency responsible for overseeing drug safety and approval. Also known as Food and Drug Administration, it holds generic and brand-name manufacturers to the same standards. The FDA doesn’t just approve a drug once—it keeps watching. Through post-approval surveillance, the ongoing monitoring of drugs after they hit the market. Also known as pharmacovigilance, it, the agency tracks adverse events, checks for manufacturing flaws, and responds to reports of pills that don’t work. That’s why you’ll find articles here about how the FDA catches faulty generics, why some drugs are kept brand-only, and how drug shortages happen.

Pharmaceutical manufacturing isn’t just about making pills. It’s about controlling every variable: the source of active ingredients, the cleanliness of the facility, the humidity during packaging, even the type of water used. A tiny mistake—like contamination or inconsistent dosing—can lead to serious harm. That’s why companies use automated systems, real-time testing, and batch tracking. And it’s why some drugs, like those with a narrow therapeutic index, medications where the difference between a safe dose and a toxic one is very small. Also known as NTI drugs, it, can’t be swapped out for just any generic. Even small differences in how a drug is made can change how your body reacts.

What you’ll find in the posts below isn’t a dry list of factory processes. It’s real-world stories about what goes wrong—and right—in drug production. You’ll read about how the FDA catches unsafe generics, why some pills cost more than others even when they’re chemically identical, and how a tiny error in manufacturing can lead to a nationwide recall. You’ll learn why some people get sick from a generic version while others don’t, and how a change in the binder or coating can affect how a drug works. This isn’t theoretical. It’s about the pills in your medicine cabinet and the system that keeps them safe.

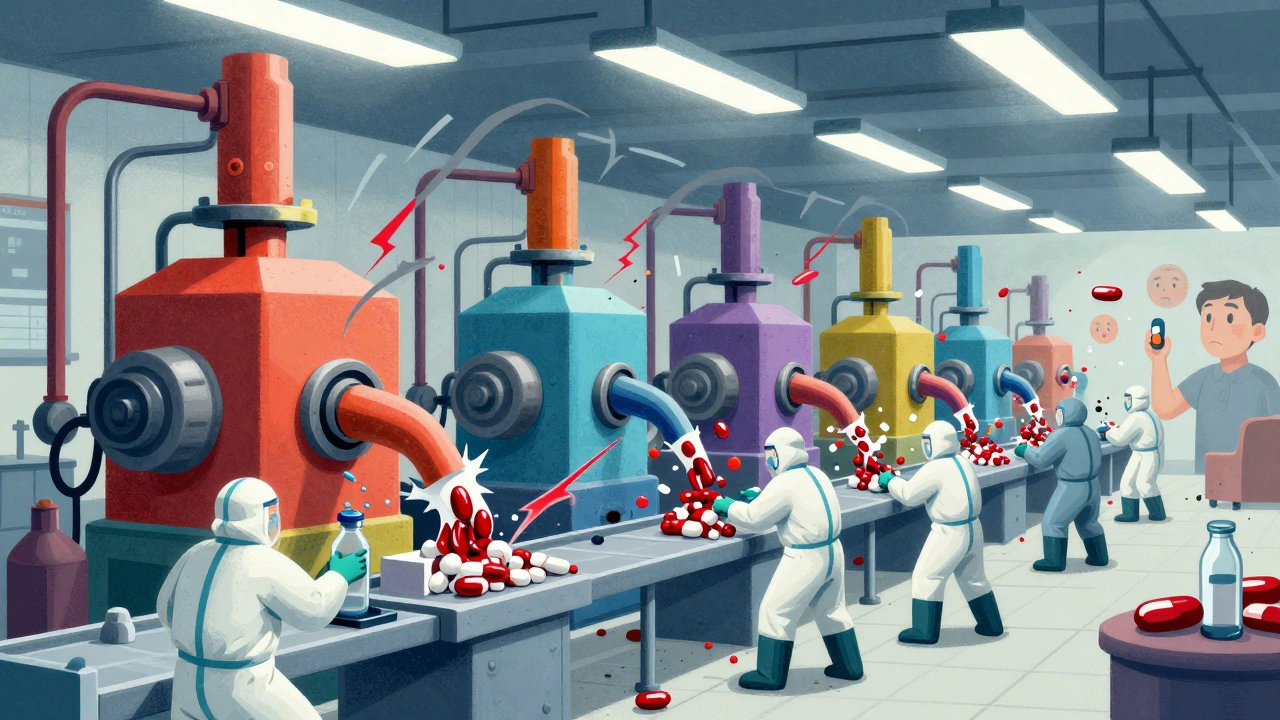

Contamination Controls: Preventing Adulteration in Generic Drug Manufacturing

Contamination controls in generic drug manufacturing prevent harmful adulteration through cleanroom standards, real-time monitoring, and strict cleaning protocols. Learn how facilities avoid cross-contamination and meet FDA requirements.

read more