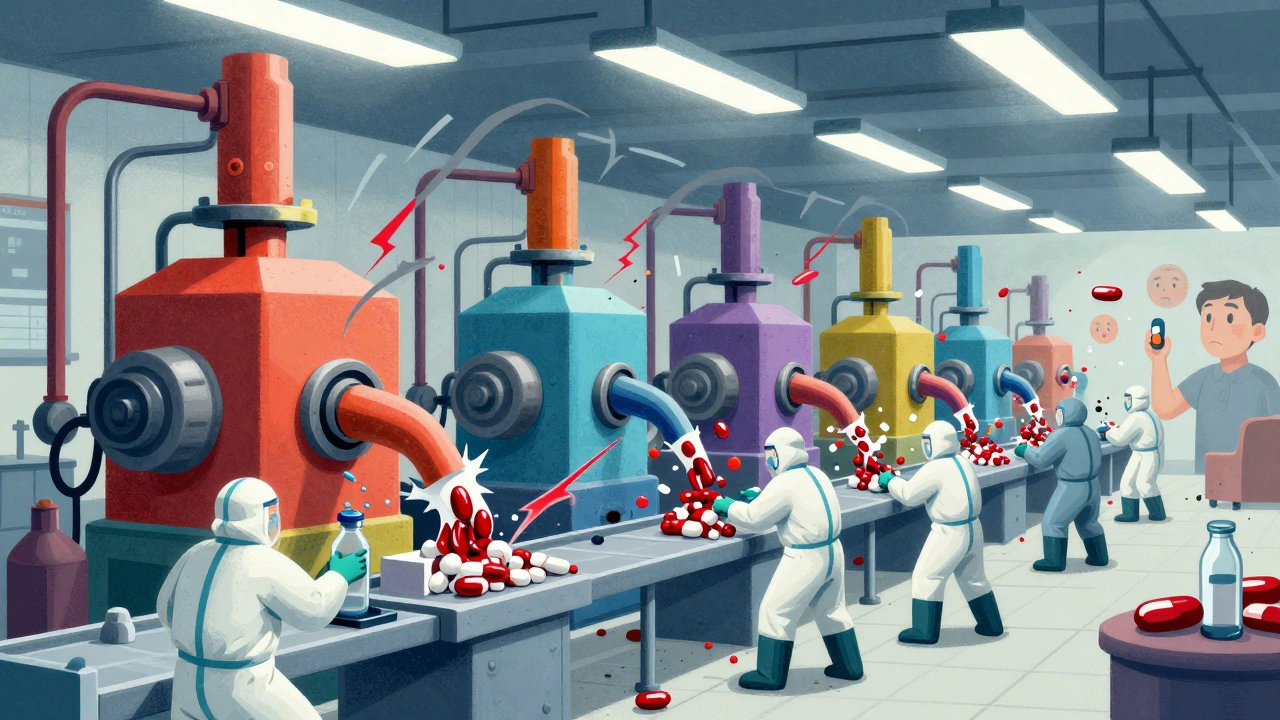

When you pick up a generic pill at the pharmacy, you expect it to work just like the brand-name version. But behind that simple promise is a high-stakes battle against invisible threats-contamination that can turn a life-saving drug into a dangerous one. In generic drug manufacturing, where profit margins are thin and production volumes are massive, contamination controls aren’t just good practice. They’re the line between patient safety and public health disaster.

What Makes Generic Drugs Vulnerable to Adulteration?

Generic drugs are copies of brand-name medications, made to the same active ingredient standards. But unlike innovator companies that often own their own facilities and have decades of process refinement, generic manufacturers frequently operate in shared plants, switching between dozens of products each year. That means one batch of blood pressure medication could be followed by a batch of antibiotics, then a hormone therapy-all in the same room, with the same equipment. This is where cross-contamination becomes a real risk. A single grain of potent steroid residue left on a tablet press can contaminate the next batch. Microbial growth in a poorly cleaned tank can turn sterile pills into breeding grounds for bacteria. Chemical residues from cleaning solvents can linger at levels too low to see but high enough to cause liver damage. The FDA defines a drug as adulterated if it’s been made under unsanitary conditions that could make it harmful. In fiscal year 2022, nearly 4 out of every 10 warning letters sent to pharmaceutical companies were for contamination issues. That’s not a glitch. It’s a pattern.The Hidden Costs of a Single Contamination Event

One bad batch can cost millions. In 2020, a nitrosamine contaminant found in the blood pressure drug valsartan triggered recalls across 22 generic manufacturers. The total loss? Over $1.2 billion. That’s not just lost product-it’s lost trust, delayed supplies, and legal battles that dragged on for years. But the real cost isn’t financial. It’s human. Imagine taking a generic version of a heart medication because you can’t afford the brand. Now imagine that pill contains a carcinogen you never knew was there. That’s why contamination control isn’t about compliance-it’s about survival.How Clean Is Clean Enough? The Science Behind Contamination Limits

There’s no universal standard for how much contamination is acceptable. It depends on the drug. For high-potency compounds like cancer drugs, even one nanogram per square centimeter is too much. That’s the equivalent of a grain of salt spread across a whole football field. To measure this, manufacturers use swabs and rinse samples to test surfaces. The goal? Less than 10 colony-forming units (CFU) of microbes per 25cm² surface area. For chemical residues, it’s under 10 parts per million (ppm). These numbers aren’t arbitrary. They’re based on toxicology studies and health-based exposure limits (HBELs) set by the EMA and FDA. Cleanrooms are classified by particle count. Aseptic filling areas need ISO Class 5-meaning no more than 3,520 particles larger than half a micron per cubic meter of air. That’s like having fewer than 3,500 grains of sand in a small swimming pool. HVAC systems push 20 to 60 air changes per hour and maintain 10-15 Pascals of pressure difference between rooms to keep dirty air from flowing into clean zones.

Technology Is Changing the Game

For years, contamination checks were done manually. Workers swabbed surfaces, sent samples to labs, and waited five to seven days for results. By then, hundreds of pills might have already been made-and shipped. Now, real-time monitoring is becoming standard. Devices like the MetOne 3400+ count airborne particles continuously. Facilities using these systems saw contamination incidents drop by 63%. Why? Because they catch problems as they happen-like a worker walking in with an uncovered cough, or a filter failing during a shift change. ATP bioluminescence systems give results in five minutes instead of a week. They detect organic residue by measuring energy from living cells. These tools are 95% as accurate as traditional cultures, but they let teams act before a batch is ruined. Even cleaning mats have evolved. Dycem CleanZone mats, placed at entrances to cleanrooms, trap 72% more foot-borne contamination than standard flooring. Simple, cheap, and effective.Human Error Is Still the Biggest Risk

No matter how advanced the tech, people are still the weak link. A 2023 survey of 217 generic manufacturers found that 47% of contamination events came from human error. That includes improper gowning, skipping cleaning steps, or mislabeling equipment. One facility switched to reusable isolation gowns to cut costs-and saw a 30% spike in gowning violations. Why? The gowns were harder to put on correctly. They had to invest $185,000 in upgraded air showers to fix it. Training matters. A 2022 survey showed it took 147 hours to train one person to use ValGenesis V2, a cleaning validation software. That’s more than three full weeks. If staff aren’t trained, the system fails-even if the tech is perfect.The Two-Speed Industry: Big Players vs. Small Manufacturers

There’s a clear divide in how companies handle contamination. The top 50 generic manufacturers spend up to $2 million on real-time monitoring systems. They’re investing in AI tools like Honeywell’s Forge Pharma, which reduced false alarms by 68% in a Merck pilot. These companies are preparing for the FDA’s 2025 deadline requiring HBELs for all products. But smaller manufacturers? Many still rely on manual swabs and paper logs. The cost of upgrading a single facility can hit $500,000. For a small company with thin margins, that’s a huge gamble. Some try to cut corners-using the same equipment for high-risk and low-risk drugs, skipping validation, or outsourcing cleaning to undertrained staff. The FDA is cracking down. In 2023, they announced a 27% increase in inspections for facilities with past contamination violations. EMA data shows 41% of generic drug applications now get deficiency letters because of contamination control gaps.

What Works: Proven Strategies for Generic Manufacturers

If you’re running a generic drug plant, here’s what actually moves the needle:- One batch at a time: Don’t switch products mid-week. Complete one batch, clean thoroughly, validate, then start the next. Facilities using this model saw 53% fewer cross-contamination events.

- Color-code everything: Use different colors for equipment used with different drug classes. One facility cut mix-ups by 65% just by painting blenders red for antihypertensives and blue for antibiotics.

- Stagger shifts: When everyone enters and exits at the same time, you get traffic jams in gowning rooms. Spread out start and end times to reduce airborne particle spikes.

- Use laminar flow hoods: These create a clean air curtain over work areas. Still cited in OSHA guidelines, they’re proven to reduce mutagenic exposure during powder handling.

- Test raw materials: Indian suppliers report 22% more contaminated raw materials than EU sources. Don’t assume your supplier’s certificate of analysis is enough. Spot-check.

The Future: AI, Sustainability, and Regulatory Pressure

The next big shift isn’t just about cleaning-it’s about predicting. AI systems are now analyzing historical data to forecast where contamination is likely to occur. Is a filter aging? Is a certain shift prone to gowning errors? The system flags it before it becomes a problem. Sustainability is also driving innovation. Waterless cleaning technologies, like those tested by GSK, cut utility costs by 22% while maintaining cleanliness. That’s a win for the environment and the balance sheet. By 2025, every generic manufacturer must implement health-based exposure limits for every product. That means calculating the exact safe level of residue for every drug, every machine, every room. It’s complex. It’s expensive. But it’s mandatory.Final Thought: Compliance Isn’t Optional

Contamination control isn’t about passing an audit. It’s about making sure the person who takes your pill doesn’t get sick because of a mistake made in your facility. The technology exists. The guidelines are clear. The cost of failure is measured in lives. The question isn’t whether you can afford to invest in contamination controls. It’s whether you can afford not to.What is the difference between cross-contamination and adulteration in generic drug manufacturing?

Cross-contamination happens when residue from one drug transfers to another during shared production-like leftover antibiotic powder mixing into a blood pressure tablet. Adulteration is the legal term used by the FDA when a drug is made under conditions that could make it unsafe or ineffective, including contamination. So cross-contamination is one cause of adulteration, but adulteration can also come from dirty equipment, poor storage, or contaminated raw materials.

Why can’t generic manufacturers just test the final product for contamination?

Testing the final product is like checking the last cookie in the batch to see if the oven was clean. It doesn’t tell you if the first 99 were contaminated. The FDA says relying only on end-product testing is a violation of CGMP rules. Contamination can be unevenly distributed-maybe only 1 in 10,000 pills is bad. You’d need to test every single one to catch it, which isn’t feasible. Prevention through clean processes is the only reliable method.

How often should cleaning validation be done?

Cleaning validation isn’t a one-time task. It must be repeated after any major change-new equipment, new cleaning agent, or a change in production schedule. Most facilities validate cleaning after every product change, and some do routine revalidation every 6 to 12 months. If a facility has a history of contamination, validation frequency increases. The key is proving consistency over time, not just checking a box.

What’s the biggest mistake generic manufacturers make with contamination control?

The biggest mistake is treating contamination control as a compliance task instead of a safety culture. That means skipping training, ignoring minor deviations, or assuming that because nothing bad happened last time, it won’t happen again. The most successful facilities treat every near-miss as a warning sign and invest in people as much as in machines.

Can small generic manufacturers afford modern contamination controls?

Yes-but not all at once. You don’t need a $2 million AI system to start. Begin with color-coded equipment, staggered shifts, and Dycem mats. Upgrade to real-time particle counters one unit at a time. Focus on high-risk products first. Many small manufacturers use shared validation services or partner with contract labs to reduce upfront costs. The goal isn’t to be the most advanced facility-it’s to be consistently safe.

What happens if a generic drug manufacturer fails an FDA inspection for contamination?

The FDA can issue a Warning Letter, which is public and damages reputation. If unresolved, they can block new product approvals, halt shipments, or even shut down production. In extreme cases, the company may be barred from selling drugs in the U.S. for years. The 2022 Warning Letter to Apotex Inc. for inadequate contamination controls led to multiple product recalls and a 3-year delay in new drug submissions.

Are there any low-cost ways to improve contamination control right now?

Absolutely. Start with simple things: enforce strict gowning rules, install door mats at every entrance, label every piece of equipment with color codes, and train staff to report even small spills immediately. Keep cleaning logs detailed and review them weekly. These steps cost almost nothing but can cut contamination incidents by 30% or more. Culture change starts with small, consistent actions.

15 Comments

This is wild-imagine taking a pill that could be laced with someone else’s medicine just because a cleaner forgot to wipe a machine. 😱 We’re talking life-or-death stuff here, and it’s happening in plain sight. Thanks for laying it out like this.

That stat about 47% of contamination events coming from human error? Chilling. It’s not the tech that’s failing-it’s the culture. You can have the fanciest air filters in the world, but if someone skips gowning because they’re late for coffee, it all crumbles. This isn’t just compliance-it’s a mindset. And we’re not training people to think like guardians of health. We’re training them to check boxes.

I’ve seen facilities where the cleaning logs are handwritten in pencil. Pencil. Like it’s a grocery list. No wonder things slip through. The real innovation isn’t in the sensors-it’s in the accountability.

And don’t even get me started on the ‘we’ve never had a problem before’ mentality. That’s how disasters begin. One tiny oversight. One skipped swab. One ‘it’s fine’ whispered under breath. Then boom-10,000 people get a carcinogen they didn’t sign up for.

Color-coding equipment? Genius. Simple. Cheap. Effective. Why didn’t we think of this 20 years ago? Because we were too busy optimizing profit margins to care about the person swallowing the pill.

It’s not just about the FDA. It’s about the grandmother in Ohio who takes her blood pressure med because she can’t afford the brand. She deserves better than a gamble.

And let’s be real-when a company cuts corners on cleaning validation, they’re not saving money. They’re just borrowing trouble from the future. And the interest? Lives.

I’m not saying every small manufacturer is negligent. But the system is rigged to reward the cheapest, not the safest. And that’s a moral failure, not an economic one.

We need to treat contamination like we treat nuclear waste. Not ‘maybe it’s clean enough.’ Not ‘we’ll test later.’ Not ‘it’s probably fine.’ Absolute zero tolerance. Period.

And yes, I’m mad. Because if this were happening in food production, we’d be rioting in the streets. But pills? We just shrug and say, ‘Oh well, generics are cheap.’

It’s time we stopped normalizing risk.

So let me get this straight-we spend $2 million on AI to detect if someone sneezed near a blender… but we still let people wear the same scrubs for three shifts? 🤡

Also, ‘Dycem mats’? Sounds like a new brand of yoga mat. Next they’ll sell ‘CleanZone’ socks.

Meanwhile, my local pharmacy still sells expired insulin. But hey-at least the tablet press is ISO Class 5.

OMG this is so important!! I just learned all this and I’m like… why isn’t this on TV?? Everyone should know this!! 🙏 I’m gonna tell my mom to always check the manufacturer on her meds now!!

Also, color coding?? That’s so smart!! I wish my kitchen had color coded spatulas!! 😭

The real question isn’t whether we can afford contamination controls-it’s whether we can afford to keep pretending this isn’t a systemic failure of values.

We treat drugs like commodities, not sacred tools of healing. We optimize for speed, cost, and scale, then act shocked when people get sick. The science is clear. The standards exist. The tools are available.

What’s missing is the moral courage to prioritize human life over quarterly earnings. That’s not a technical problem. It’s a cultural one.

And until we change that, no amount of ATP bioluminescence or laminar flow hoods will fix what’s broken.

Bro… what if this is all a scam? Like… what if the FDA and big pharma are using ‘contamination’ as an excuse to shut down small Indian and Chinese labs so Big Pharma can keep their monopoly? I mean… why are all the warning letters going to generics? Brand names never get flagged, right? Coincidence? I think not. 🤔

Also, ‘health-based exposure limits’? Sounds like a fancy way to say ‘we’ll let you poison people as long as it’s below the magic number.’

And Dycem mats? That’s just a marketing gimmick. They’re selling fear. Same as those ‘organic’ toothpaste ads.

So 4 out of 10 warning letters are for contamination? That means 6 out of 10 are for other stuff. So most of these places are just garbage. Why are we even buying generic? Just pay for the brand. At least then you’re paying for a company that gives a damn.

Also, ‘nanogram per square centimeter’? That’s less than a speck of dust. You’re telling me we’re supposed to believe these places are clean? They’re not. They’re just good at lying to inspectors.

Okay, but what if this is all just a distraction? 🤔 What if the real problem is that we’ve outsourced our healthcare to corporations that see people as line items? Contamination is just the symptom. The disease is capitalism. We turned medicine into a product. And products are designed to be cheap, not sacred.

And don’t get me started on ‘AI predicting contamination.’ That’s not innovation-that’s automation of neglect. We’re letting machines do the moral work so humans don’t have to feel guilty.

Also, ‘color-coded blenders’? Cute. But when your CEO is making $20M a year while your nurse can’t afford her own insulin… maybe we’re fixing the wrong thing.

I’m not mad. I’m just… heartbroken.

This is the most important post I’ve read all year. Every point is accurate, well-researched, and urgently needed. The fact that we tolerate this level of risk in something as fundamental as medication is a national disgrace. There is no excuse for cutting corners on human health. We must demand better-from regulators, from manufacturers, and from ourselves as consumers. No more passive acceptance. No more ‘it’s just generic.’ It’s not just a pill. It’s someone’s life.

Thank you for writing this. I work in a small clinic, and I see patients who rely on generics every day. I never knew how much goes into making sure those pills are safe. It’s terrifying to think how easily things could go wrong. But I’m glad there are people out there trying to fix it-even if it’s slow. Small steps matter. Color-coding, staggered shifts, better training-these aren’t just ‘best practices.’ They’re lifelines.

To the small manufacturers reading this: you’re not alone. There are people who see you. And we’re rooting for you to get the support you need.

WHOA. I just read this and I’m literally shaking. 🙌 This is the kind of stuff that should be on the news, not buried in a technical blog. We’re talking about PEOPLE here. Not data points. Not profit margins. LIVES. I’m sharing this with everyone I know. If you take a pill today, you owe it to yourself to know this story. Thank you for shining a light on this.

so like… i had no idea about any of this. i just thought generic = cheaper. but now i get it. it’s not just about price, it’s about safety. and the color coding thing? genius. i’m gonna start doing that with my kitchen stuff lol. also, dycem mats? i need those for my house. 😅

Wow. I just cried reading this. 💙 I’ve been on so many meds over the years, and I never thought about where they came from. It’s scary, but also… kind of beautiful that so many people are working so hard to keep us safe. Even the small things-like wiping a machine or wearing the right gloves-those matter more than we know. Thank you for reminding us that care is in the details.

It’s worth noting that the FDA’s 2025 HBEL mandate isn’t just bureaucratic red tape-it’s the first time they’ve legally required manufacturers to quantify the safe threshold for every residue, every drug, every surface. That’s a seismic shift. It forces transparency. It forces accountability. It forces companies to prove, not assume, that their processes are safe.

And that’s why the real battle isn’t in the cleanrooms-it’s in the boardrooms.

Exactly. And the fact that they’re forcing HBELs means they finally admit: we can’t just rely on ‘we’ve always done it this way.’ We need science, not tradition. That’s progress-even if it’s painfully slow.