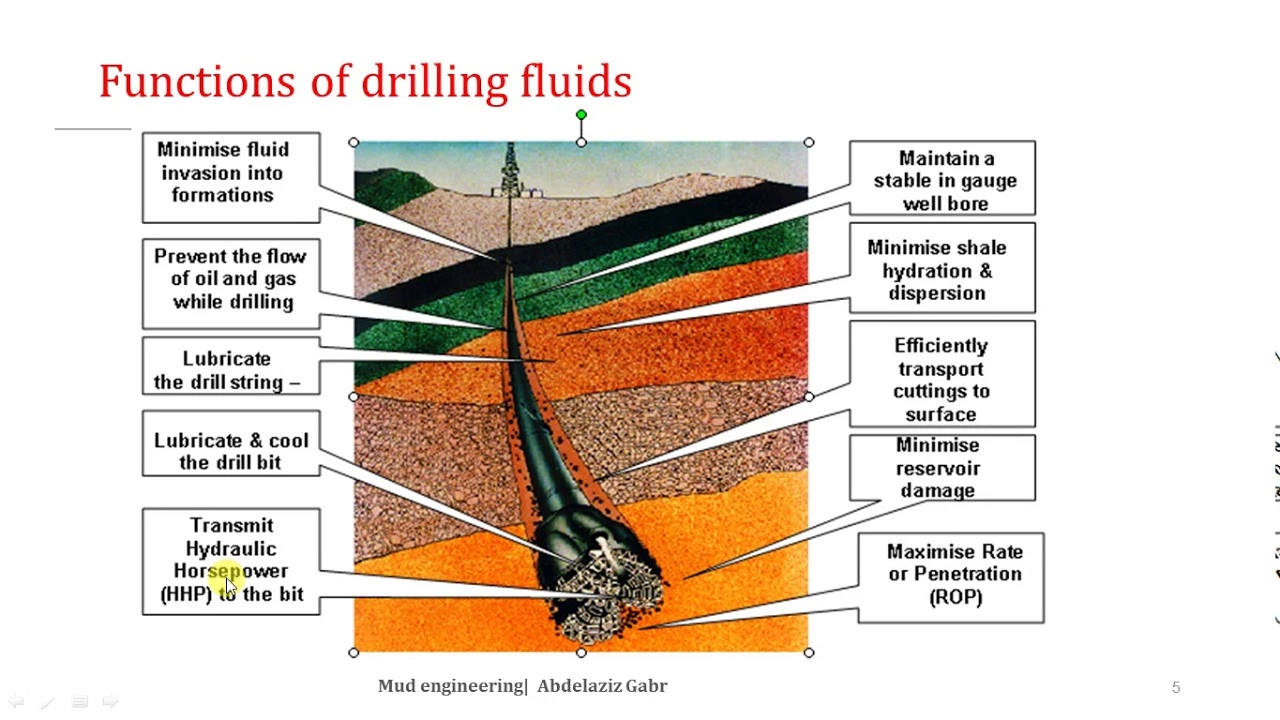

Drilling fluids: what they do and why they matter

Ever wonder why drilling rarely fails completely despite hitting unpredictable rock? A big part of that is drilling fluids. They cool the bit, lift cuttings, control formation pressure, stabilize the hole and carry data back to the surface. Get those fluid properties wrong and you can expect stuck pipe, lost circulation, or a messy environmental problem.

Common types and when to use them

There are three main families: water-based muds (WBM), oil-based muds (OBM), and synthetic-based muds (SBM). Water-based is cheap, easy to handle, and fine for most soft formations. Oil-based gives superior shale inhibition and temperature stability, so you’ll see it in sticky shales or deep high-temperature wells. Synthetic-based aims to combine OBM performance with lower environmental footprint—useful where regulations limit oil use. Besides base fluid, mud systems include weighted fluids (add barite) when you must increase mud weight to control formation pressure.

Choosing a fluid depends on formation type, well depth, environmental limits, cost and disposal. Ask: how reactive is the shale? What’s the bottom-hole temperature? How strict are local waste rules? Those answers point you to WBM, OBM or SBM.

Key properties to watch on site

Keep tests short and frequent. Mud weight (density) tells you if you’re balancing formation pressure—measured in ppg or g/cm3. Viscosity and rheology control cuttings transport; measure these with a viscometer and track plastic viscosity and yield point. Gel strength shows if cuttings will settle when pumps stop. API filtration and cake thickness reveal how much fluid invades the formation. pH affects additives and corrosion control. Solids content matters: too many drilled solids raise viscosity and reduce hydrostatic control.

Solids control equipment—shale shakers, desanders, desilters and centrifuges—keeps your mud clean. Use a shaker first to remove coarse cuttings, then hydrocyclones and centrifuges for finer solids. Proper screen selection and regular shaker maintenance save time and reduce chemical use.

Common additives and simple tips

Barite for weight, bentonite for viscosity and filter cake, LCMs (lost circulation materials) for sealing fractures, shale inhibitors (like potassium salts) to stop clay swelling, and biocides to prevent bacterial breakdown. Additives work, but measure before and after dosing. Too much polymer or too many fines will wreck mud properties.

Practical on-site advice: test the mud every shift, keep clear records, avoid over-weighting the mud to fix problems, and use controlled dilution rather than aggressive chemical fixes. When switching base fluids (WBM to OBM), plan for cleaning and disposal—cross-contamination causes headaches.

Safety and environment matter. Always follow PPE rules for handling chemicals, contain spills, and follow local disposal rules for spent mud and cuttings. Small practices—tight lids, labeled drums, secondary containment—cut risk and cost.

Good mud management is simple: test often, clean solids, dose carefully, and match fluid type to the formation and regulations. Do that and drilling runs smoother, safer, and cheaper.

Calcium carbonate in the oil and gas industry: An essential component

As a vital component in the oil and gas industry, calcium carbonate plays a crucial role in various aspects of the drilling process. It helps in stabilizing the drilling fluid, preventing the formation of gas hydrates, and maintaining the desired density of the fluid. Additionally, calcium carbonate is an effective bridging agent, sealing off porous sections of the wellbore to prevent fluid loss. Furthermore, it aids in the neutralization of acidic components in the drilling fluid, ensuring the well's stability and safety. Overall, calcium carbonate's versatility and effectiveness make it an indispensable component in the oil and gas industry.

read more